Products and processing

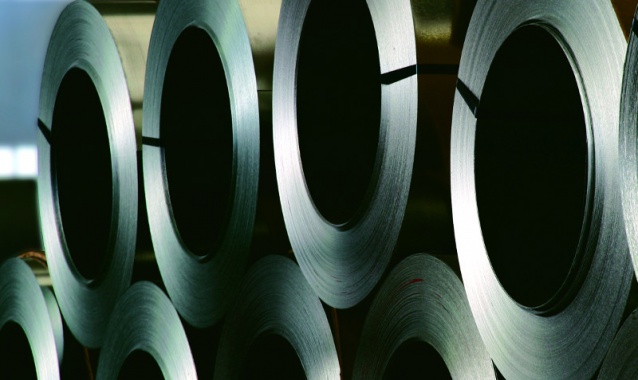

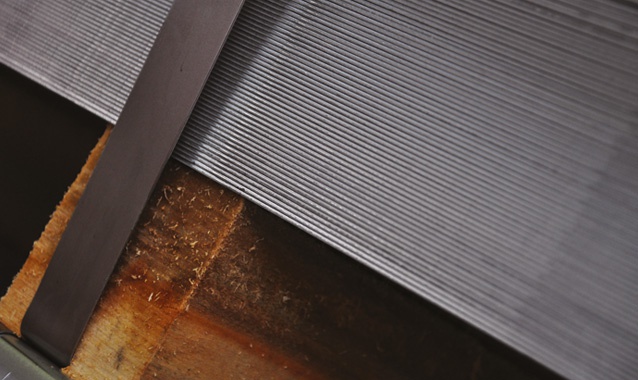

ArcelorMittal CLN offers a complete and innovative range of flat carbon steel products including hot rolled, cold rolled and coated steels, serving all market sectors including automotive, household appliances, construction, and general industry.

Our production includes strips and plates cutting facilities of the main materials: from hot rolled steels (standard black or high-strength, pickled), cold rolled, metal coated, pre-painted, electrical steel and floor plates.

Strip and sheet cutting capacity

Thickness from 0.30 mm to 20 mm. For some processing the minimum thickness starts from 0.15 mm.

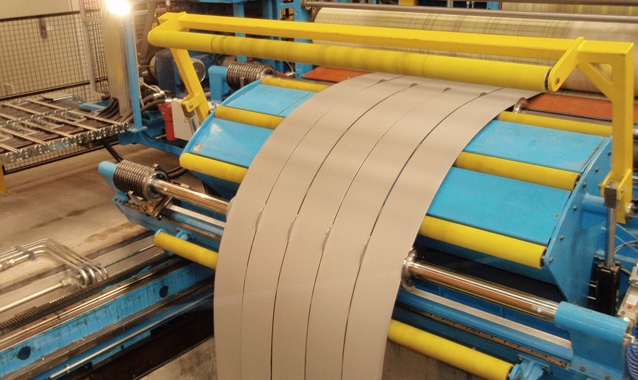

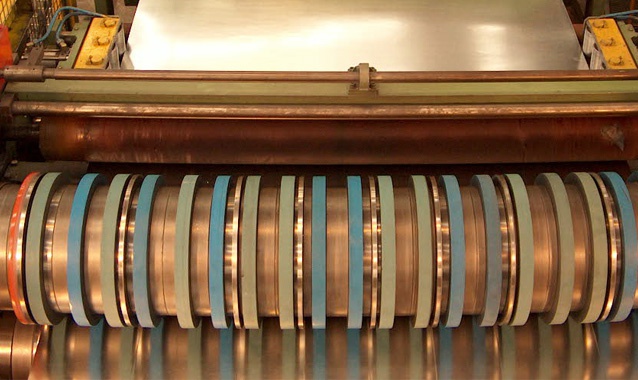

Strip cutting

width from 30 mm to 2100 mm. For some processing the minimum width starts from 20 mm.

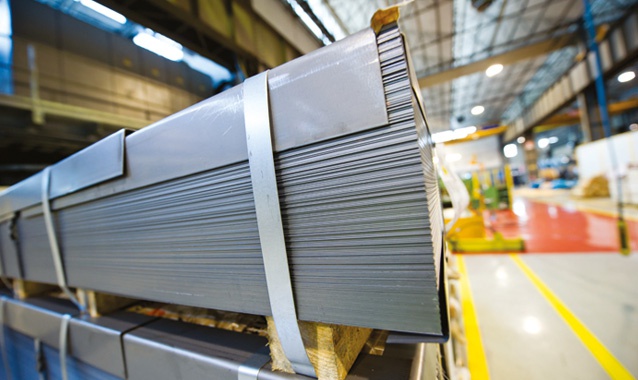

Sheet cutting

widths up to 2250 mm and lengths up to 16000 mm.

Other processing

The following facilities are also available:

Trapezoidal and parallelogram cutting facilities

Max 30° angle (automatic)

Angle > 30° (manual)

Polygon cutting facilities | robotized shearinga

Thickness from 0.5 mm to 3 mm.

Width up to 1000 mm. Length up to 3000 mm.

The feasibility of the formats requested is assessed by our engineering department.

Press blanking facilities

Possibility of blanking directly from strips. Press capacity up to 1600 Tonnes.

Assessment of specific customer requests is available.

Laser/oxycut

Round cuts (discs) and other shapes are available upon assessment of customer’s technical specifications.

We have specialized cutting centres with fully automatic machines that can handle various configurations.

Tailored Blanks

Available upon request.

Pre-painted/Protective film

Processing of pre-painted material with possible application of protective film.

Thickness from 0.25 mm a 6 mm. Width up to 2000 mm.

The high customization granted by our processes enables the production of complex components, such as steel sheets for the construction industry (cladding of industrial premises, sports centres ...).